WHY YOKAN

4 Reasons to Choose Us

You can find plenty of CNC machining shops, easily by a few clicks online, but finding one you can actually count on is another story. If you’ve ever worked with an unreliable machining partner, then you know how stressful and frustrating it can be every time parts are unavailable, out of specification, or delayed.

At YOKAN, we don’t take it for granted with each chance to serve our customer, instead, we treat it a privilege, and an opportunity to build a long-term partnership with them. Here is a glimpse of how we have striven to raise the bar, so that when you choose to work with us, we can provide you with reliability and peace of mind.

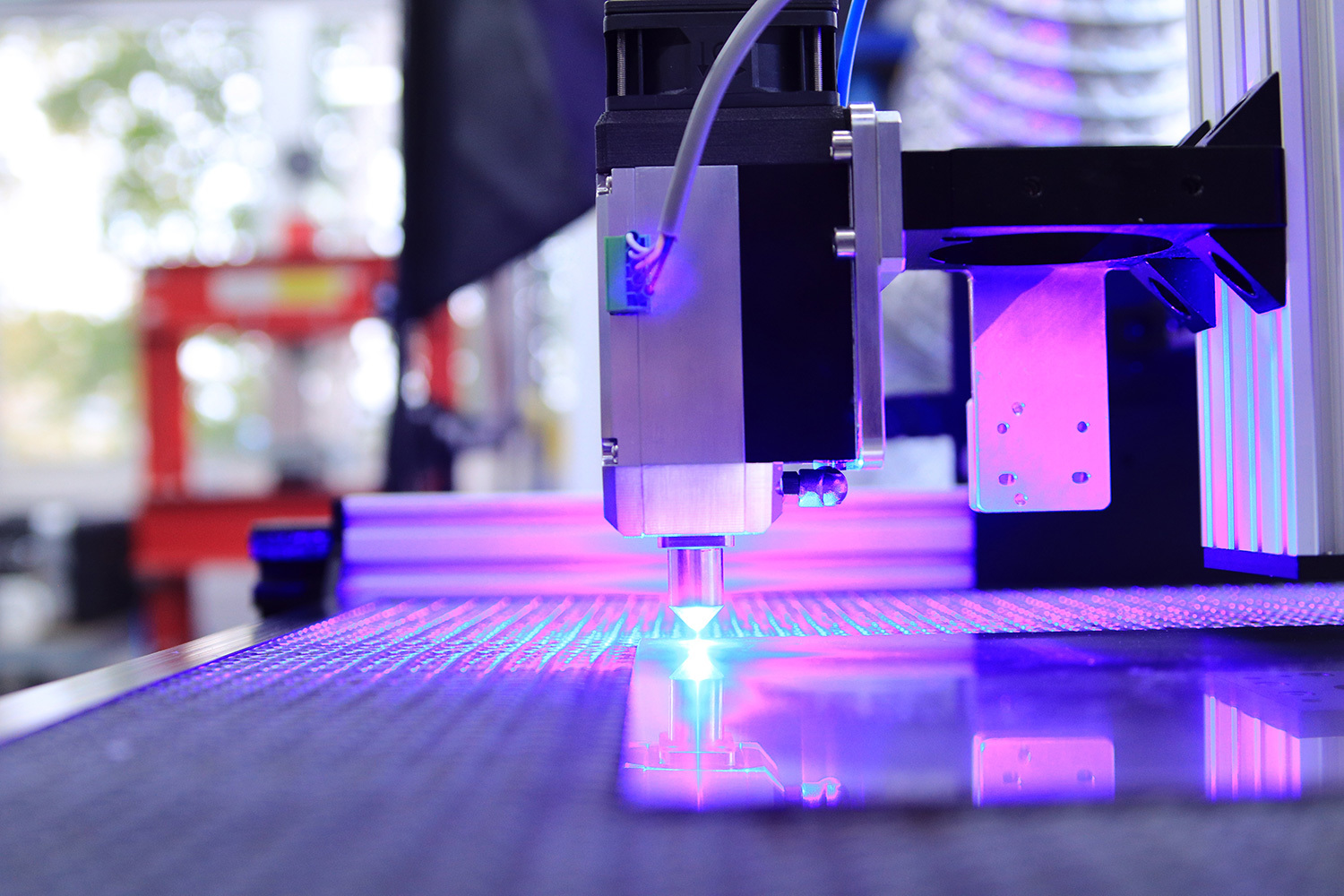

World-class Equipment

YOKAN constantly invests in industry leading equipment, 100% of our production equipment for fine machining is from world top 10 brands, including FFG-FEELER, MAZAK, and MAKINO horizontal mill set to be in place by 2023. When it comes to inspection equipment, we have ZEISS CMM to assure quality of our premium parts and process.

Cutting Tool Expertise

If you want to eat well, you need to have a good tooth. Cutting tool is like tooth for machining. Since 2008, YOKAN has been authorized distributor for many world-class tool brands, including SANDVIK, KENNAMETAL, WIDIA, and YG. With our deep knowledge in this field, we are capable of swiftly developing a dedicated tool solution for any application, reducing cutting times, increasing machining accuracy, and changing challenges into success.

Finest Technician and Teamwork

Our major technicians possess 10+ years of experience on average in the industry. We work differently than other services and ask questions to help our customers build better and more cost-effective parts before we start manufacturing.

Unrivaled Supply Chain

With our strategic location in Dongguan city, a manufacturing hub of precision metal and plastic products in south China, YOKAN enjoys unrivaled supply chain nearby, from talent pool of skilled technician, through to material, treatment, and wide range of surface finish for different industry applications.

FAQ

Your Questions Answered

We’ve put together some commonly asked questions to give you more information about our service and business practices.

If you have a question that you can’t find the answer to, please use the Contact Us page.

What tolerance can you hold?

At YOKAN, our standard prototype and production machining tolerance is +/-0.10 mm (0.005 in.). But if you need greater accuracy, there’s our standard precision or production machining tolerance of +/-0.05 mm (0.002 in.). We're also able to hold +/- 0.01mm (0.0005 in.) on reamed holes, and +/- 0.05mm (0.002 in.) on feature locations, provided those features are machined on the same side of the part. Depending on the part geometry and material, however, we can often achieve even greater accuracy, provided you make us aware of your requirements. For these and other exceptions, please be sure to note them on your part design when you upload the file(s) for quoting.

Does YOKAN manufacture in higher-volume quantities?

We focus on prototypes to low-volume production and can do large runs. All our parts, from one -to 100 -to 1,000+ are always delivered with production-quality finish.

If I do not have a CAD model, can you quote/ fabricate my parts?

Yes, we can work directly from your drawings.

How fast can I get my order?

Lead time for standard orders is 10-15 days. Expediting options are available, including emergency service-down to as fast as 1-2 business days, depending on complexity of work and materials.

How long is a quote valid?

Our quotes stand firm for 7 days from the date of issue.

How do you pack your machined parts?

We use different techniques for packaging your metal and plastic parts.Usually each part will get wrapped with plastic film before being packaged with foam sheet and labeled with part number, then packed into sized carton so that parts have little room to shift or slide to get damaged while in transit.

In case of intricate part tend to break or deform easily, we can package each part with individual bag before putting into small container, and then wooden case ready for shipping. Sometimes, packing one box inside a larger one with additional packaging material around it also can provide extra protection.

What are your payment terms?

YOKAN offers Net 30 payment terms for established customers with good credit.

Need a help

YOKAN for Peace of Mind.

Are you looking for a partner to produce high quality, high-tolerance products or complex parts? Contact us today and experience the YOKAN difference!

We always welcome you to the factory to meet our team and see all our facilities, so you can feel comfortable that we are the right fit for your project. Please contact us to schedule a site visit.

If you are too busy for a site visit, you can also make an appointment with our sales representative to tour our factory via online meeting.

Contact Us