QUICK FACTS

Your Parts, Our Expertise.

We are machining experts, specializing in low volume parts typically ordering quantity from 1 piece up to 1,000. We constantly fine-tune our processes and programs to deliver the performance you expect, with competitive pricing and great turnaround times. Our finest engineers and craftsman deliver components with high level accuracy that save you time, improves your bottom-line, and helps you gain efficiency.

We routinely hold tight tolerances down to ±0.01 mm ( ±0.0004’’ ), with inspection result of certainty controlled by best-in-class metrology equipment like ZEISS CMM

We are passionate about your success with around the clock service. In most cases

we turn your quote around in 8 hours.

By optimizing manufacturing program and reducing waste in process that we pass along,

we strive to save you time and money up to 30% comparing with your present budget.

Our highly qualified team consists of 70+ members with 10+ years of experience on average in the industry

WHAT WE DO

Custom Machined Parts Manufacturing Made Simple.

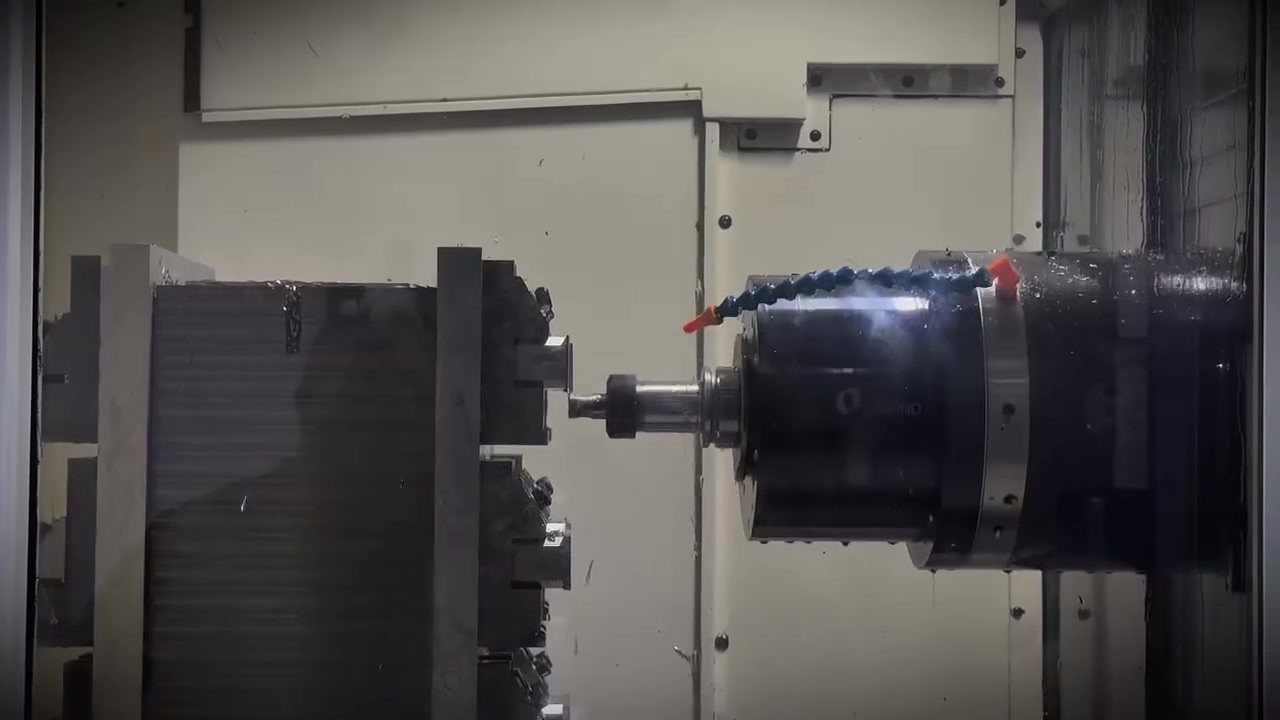

With our wide-range of capabilities and one-stop value-added service, YOKAN makes it faster, easier, and more cost-effective to source the custom machined parts you need, precisely when and how you need them.

Up to 5-Axis CNC milled and turned parts in as fast as 3-5 days

Swiss turning

Sinker and wire EDM machining

Best known for our expertise with complex parts and difficult to machine materials

Who We Are

Reliable Manufacturing Partner You Can Count On

YOKAN Precision Technology (Dongguan) Co., Ltd is a machining enterprise located in Dongguan city, China, specializing in lower volume custom precision machining. Founded in 2018, YOKAN began as a small shop with two mills squeezed in a 60 square meters garage, swiftly establishing a reputation for each order’s superior craftsmanship. Fast forward four years later, we are proud to have a state-of-the-art 3,000 square meters temperature and dust controlled facility to produce and assemble the most intricate parts.

Our capabilities include up to 5-axis CNC milling, CNC lathe, Swiss machining, sinker and wire EDM, serving a vast range of industries, including medical, dental, electronics, communication, transportation, aerospace, and more. Each year, we invest in the latest industry equipment and standards to develop capacity and capability to better serve your needs.

We also invest heavily in quality, we are ISO 9001 certified. Our quality is backed physically by a ZEISS CMM, optical comparator, and the finest gauges and metrology equipment, yet equipment is easy to come by and does not differentiate us, talent, experience and a passion for manufacturing excellence is the rare commodity today.

We put customer first, with quality, cost-effectiveness, and speed at the forefront of our operations, our skilled engineers and manufacturing technicians are dedicated to turn your project into a resounding success.

Explore more